Graphene PRAM key to high-density, energy-efficient memory chips

Graphene PRAM key to high-density, energy-efficient memory chips

We need the memory chips in phones, laptops, electronic devices and any smart gadgets need to be small, fast and draw as little power as possible and today’s computing technology, however, cannot scale to satisfy such big data applications with the required throughput and energy efficiency. The next technology frontier will be monolithically integrated chips with three-dimensionally interleaved memory and logic for unprecedented data bandwidth with reduced energy consumption for years silicon chips have delivered on that promise.

But to dramatically extend the battery life of mobile gadgets, and to create data centers that use far less energy, engineers are developing memory chips based on new nanomaterials like graphene because silicon can’t match with that capabilities, So demonstrate post-silicon materials and technologies that store more data per square inch and use a fraction of the energy of today’s memory chips.

The unifying thread in many experiments is graphene, an extraordinary material isolated a decade ago but which had, until now, relatively few practical applications in electronics.

What different between normal RAM and PRAM?!

Memory chips store data as a string of ones and zeroes Today the most memory chips are based on silicon, and come in two basic types volatile and non-volatile. Volatile memory, such as random-access memory (RAM), offers fast but temporary storage When the power shuts off, the zeros and ones vanish.

Non-volatile memory, such as the flash memory in cell phones, is slow but stable. Even if the battery expires the data remains.

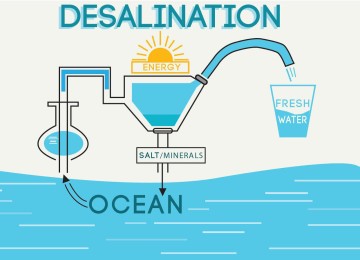

In RRAM ( Resistive Random Access Memories ) chips, tiny jolts of electricity switch certain metal oxides between resistive and conductive states. When the metal oxides resist the flow of electrons, that creates a zero. When the materials conduct electrons, that is a one. RRAM is fast, like volatile silicon memory, but like flash memory it retains stored data when the power is turned off.

This work demonstrates the possibility of constructing non-volatile RRAM while densely storing data without consuming more energy.

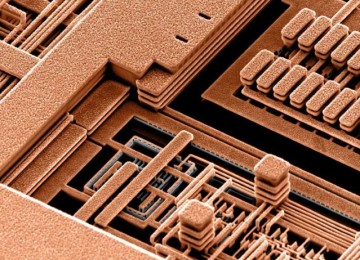

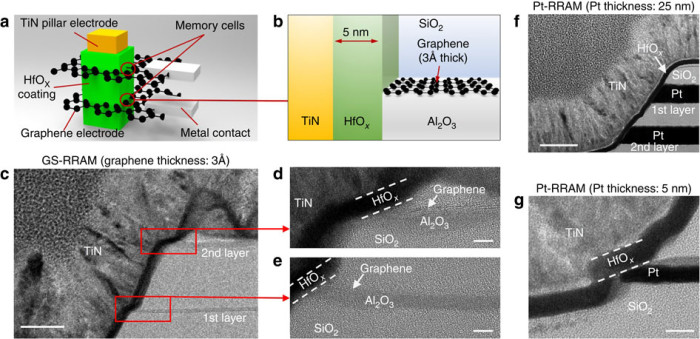

Graphene RRAM structuration

Graphene PRAM creates super RAM:

We depend in graphene to create super RAM because we exploit the atomically thin nature of the graphene edge to assemble a resistive memory (~3 Å thick) stacked in a vertical three-dimensional structure (RRAM) based on metal oxide have shown considerable promise as a possible successor to Flash because of better endurance, retention, speed, lower programming voltages and a higher device density. These devices also use material sets and fabrication temperatures that are compatible with today’s silicon technology and offer the opportunity for future monolithic 3D integration with logic computation units.

Graphene, an atomically thin crystal lattice of carbon atoms, is known for its unique electronic properties. Both graphene and graphene oxides have been used in various memory devices, including RRAM, ferroelectric memory, and Flash memories as electrodes and oxides.

The density of a 3D vertical RRAM array is known to be mainly limited by the sheet resistance and the layer thickness of the plane electrode, and not so much by the lithographic half-pitch, as it is in two-dimensional (2D) architectures. This is due to the limitation of the pillar electrode resistance and the non-vertical etching angle resulting from trench etching through metal planes16. Graphene’s sheet resistance per thickness (125 Ω per square at a monolayer thickness of 3 Å when doped18) is significantly lower than that of any metal. All metal films are known to exhibit a steep exponential increase in sheet resistance as the thickness falls below 5 nm (ref. 15). Graphene is also significantly easier to etch vertically than metal during pillar formation. Using a well-accepted reliability projection15—assuming programming voltage of 3 V, SiO2 thickness of 6 nm, half-pitch of 22 nm and 1° of etching angle improvement—a maximum of 200 stacks will be possible for GS-RRAM as compared with the 60 stacks possible with conventional bulk-metal-based 3D RRAM